Click or tap image to expand

Gemini® Twin Bore IR Heaters

Refine Results

(5 filters)Element Wavelengths

No options available for this section based on your selections

Rapid Response

Design Features Industry standard twin bore quartz tube formats with 95% heat transmittance 24-karat Gold Back Coating for targeted infrared applications White Ceramic Reflective Back Coating for extreme temperature requirements High power densities: 42/51/63.5 w/in (16/20/25 w/cm) Fast heat-up rates — Less than one minute to reach steady state conditions Very long operating life — Over 10,000 hours of highly efficient and economical continuous operation Three industry standard sizes in lengths up to 118 in. (3000mm)

Rapid Response

Design Features Industry standard twin bore quartz tube formats with 95% heat transmittance 24-karat Gold Back Coating for targeted infrared applications White Ceramic Reflective Back Coating for extreme temperature requirements High power densities: 42/51/63.5 w/in (16/20/25 w/cm) Fast heat-up rates — Less than one minute to reach steady state conditions Very long operating life — Over 10,000 hours of highly efficient and economical continuous operation Three industry standard sizes in lengths up to 118 in. (3000mm)

| Minimum Spacing between Heaters in Array Assemblies and CRA Linear Housings. | |||

|---|---|---|---|

| Twin Bore Tube Size | 18 x 8 mm | 23 x 11 mm | 33 x 15 mm |

| Minimum Center to Center Spacing of Heaters Mounted in ARG Arrays (“D Dim.”) | 1.43″ | 1.63″ | 2.00″ |

| Minimum Center to Center Spacing of Heaters Mounted in CRA Linear Housings | 4.00″ | 4.00″ | 4.00″ |

Scroll for more

Construction Styles

No options available for this section based on your selections

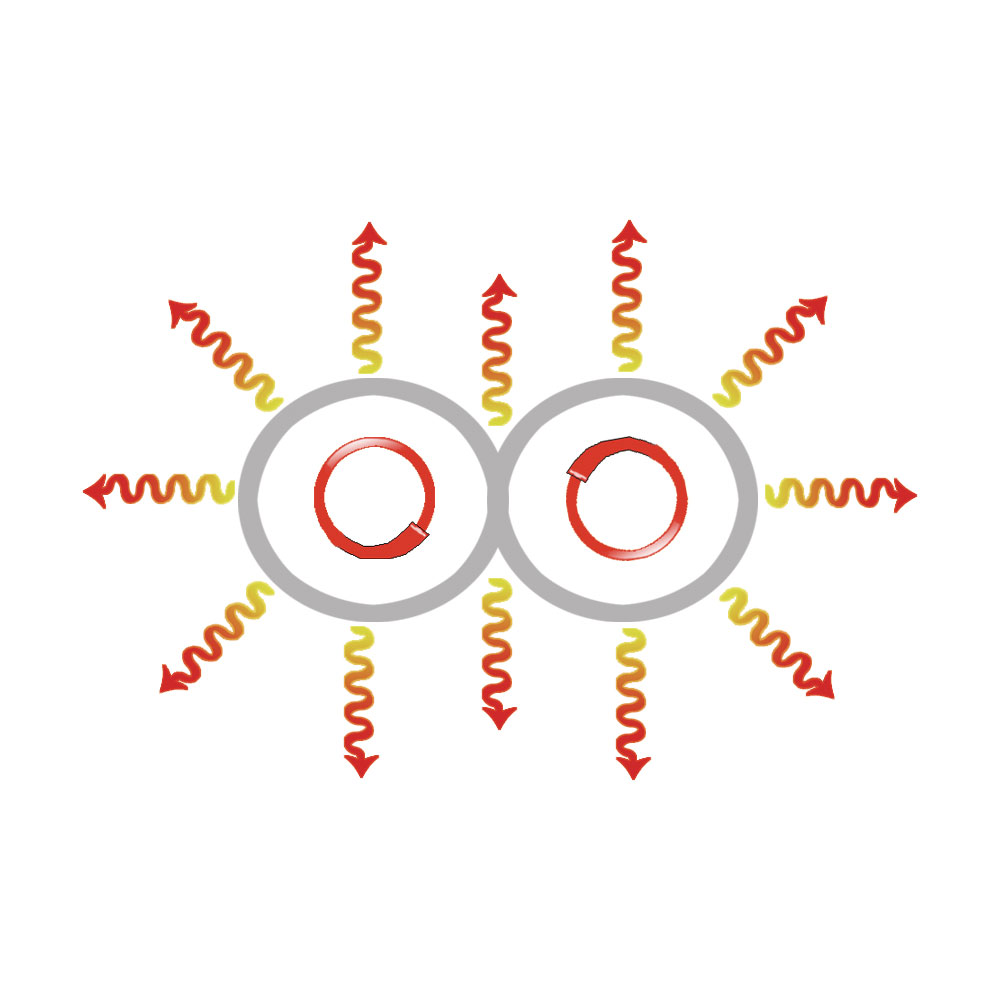

Clear Tubing without Coating

Back Coating: None

Maximum Coil Temperature: 2012°F (1100°C)

Feature: 360° Heat Radiation Typical Applications: PVC Panel Coating Cure Curing Coating on Rubber Seals Powder Coating Industry Wood Processing Industry Culinary Arts Industry

Clear Tubing without Coating

Back Coating: None

Maximum Coil Temperature: 2012°F (1100°C)

Feature: 360° Heat Radiation Typical Applications: PVC Panel Coating Cure Curing Coating on Rubber Seals Powder Coating Industry Wood Processing Industry Culinary Arts Industry

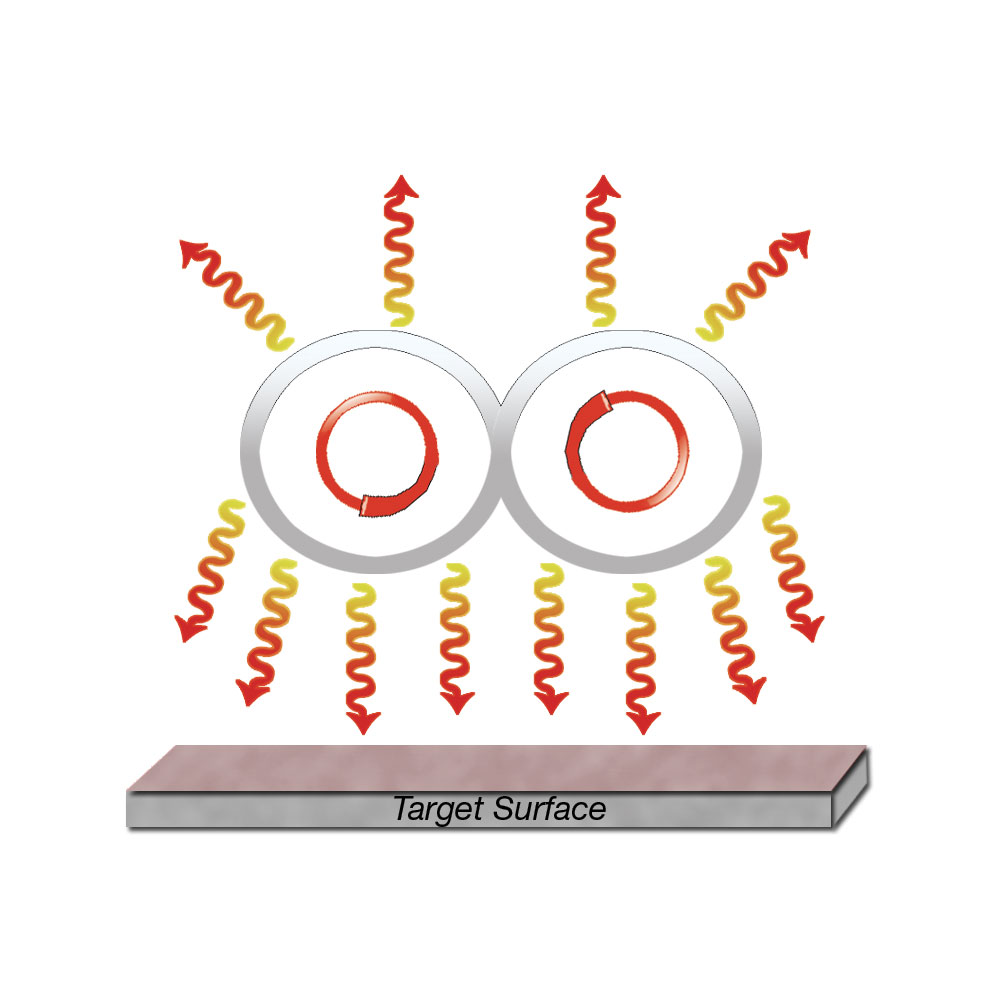

Clear Tubing with White Ceramic Coating

Back Coating:White Proprietary Formula Reflective Back Coating

Maximum Coil Temperature:2012°F (1100°C)

Feature: 75% Heat Reflection toward working surface Typical Applications: Stress Relieving of Metal Components Drying Foils Paper and Textile Industries

Clear Tubing with White Ceramic Coating

Back Coating:White Proprietary Formula Reflective Back Coating

Maximum Coil Temperature:2012°F (1100°C)

Feature: 75% Heat Reflection toward working surface Typical Applications: Stress Relieving of Metal Components Drying Foils Paper and Textile Industries

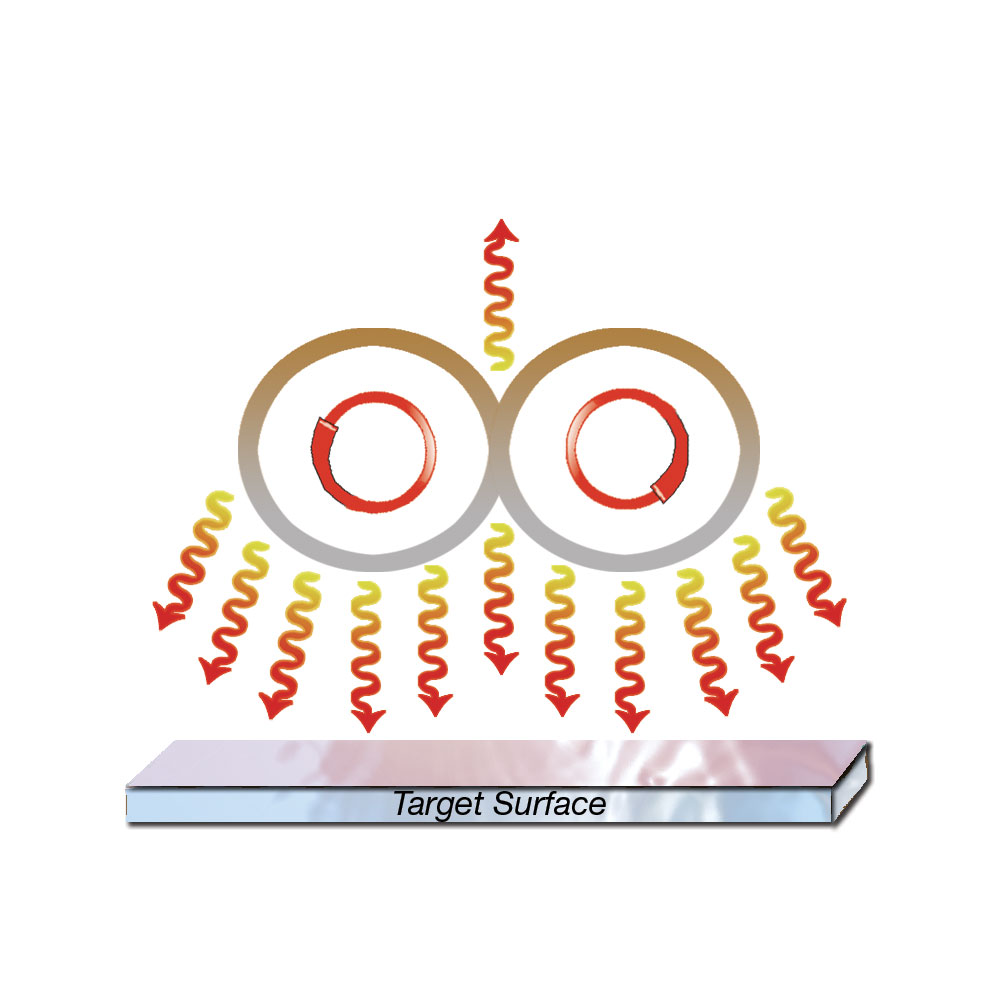

Clear Tubing with Gold Back Coating

Back Coating: 24-Karat Gold Back Coating

Maximum Coil Temperature: 1472°F (800°C)

Feature: 95% Heat Reflection toward working surface Typical Applications: Glass Processing Industry Paper and Textile Industries Plastics Industry

Clear Tubing with Gold Back Coating

Back Coating: 24-Karat Gold Back Coating

Maximum Coil Temperature: 1472°F (800°C)

Feature: 95% Heat Reflection toward working surface Typical Applications: Glass Processing Industry Paper and Textile Industries Plastics Industry

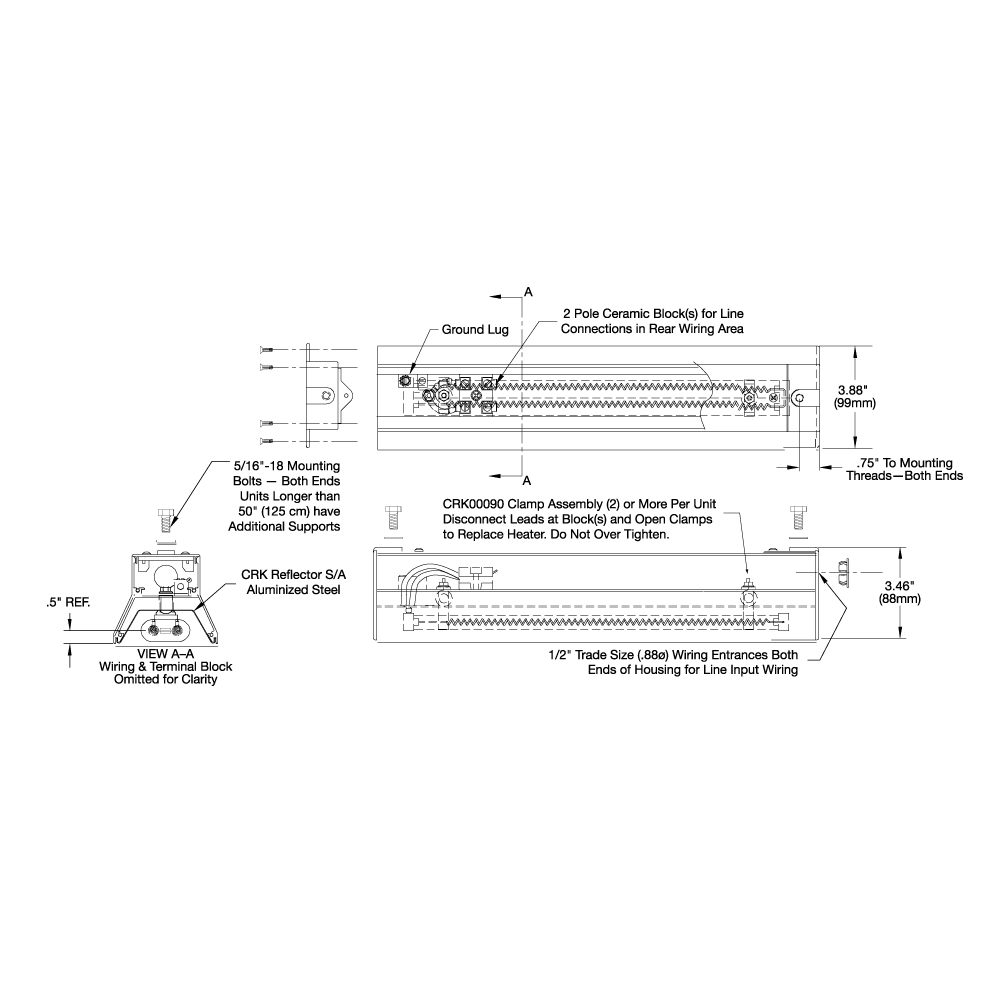

Type CRA Linear Housings

These compact assemblies have one 33 × 15 mm twin bore Gemini quartz heater mounted in front of an aluminized steel reflector at a power density of 63.5 w/linear inch. Design Features Rapid heat-up/cooldown and low residual heat retention Compact lightweight extruded anodized housing High efficiency aluminized steel reflector for harsh environments and high temperature applications Adaptable to all Gemini twin bore sizes

Type CRA Linear Housings

These compact assemblies have one 33 × 15 mm twin bore Gemini quartz heater mounted in front of an aluminized steel reflector at a power density of 63.5 w/linear inch. Design Features Rapid heat-up/cooldown and low residual heat retention Compact lightweight extruded anodized housing High efficiency aluminized steel reflector for harsh environments and high temperature applications Adaptable to all Gemini twin bore sizes

Panel Arrays

Custom panel arrays are available. Tempco will design and build to your specifications. Consult us with your requirements.

Panel Arrays

Custom panel arrays are available. Tempco will design and build to your specifications. Consult us with your requirements.

Mounting Styles

No options available for this section based on your selections

Heater Clamp

Optional 90° Lead Orientation, Shown with Optional End Mounting Clamp

Heater Clamp

Optional 90° Lead Orientation, Shown with Optional End Mounting Clamp

| Specifications and Dimensions | ||||||

|---|---|---|---|---|---|---|

| Clamp Assembly Part Number | CRK00085 | CRK00086 | CRK00087 | CRK00088 | CRK00089 | CRK00090 |

| Fits Twin Tube Size | 17 × 8 mm | 23 × 11 mm | 33 × 15 mm | |||

| Clamp Location on Tube | Center | End | Center | End | Center | End |

| Clamps Required | OAL > 39.4″ (1000 mm) |

2 per heater | OAL > 59.1″ (1500 mm) |

2 per heater | OAL > 78.7″ (2000 mm) |

2 per heater |

| Mounting Stud Threads (a) | 10-32 | |||||

| Clamp Width (b) | 0.40″ (10.2 mm) | 0.40″ (10.2 mm) | 0.60″ (15.2 mm) | |||

| Heater Mounting Height (c) | 1.20″ (30.5 mm) | 1.20″ (30.5 mm) | 1.41″ (35.8 mm) | |||

| Overall Clamp Height (d) | 2.44″ (62 mm) | 2.48″ (63.1 mm) | 2.77″ (70.3 mm) | |||

| Ceramic Insulator Diameter (e) | 0.59″ (15 mm) | 0.59″ (15 mm) | 0.59″ (15 mm) | |||

| Panel Mounting Hole Diameter | 0.375″ (9.5 mm) | 0.375″ (9.5 mm) | 0.375″ (9.5 mm) | |||

| Recommended mounting panel thickness range is 18-14 ga. | ||||||

Scroll for more

Electrical Terminations

No options available for this section based on your selections

Lead Wire

Insulated lead wire, 3/8″ stripped ends standard, oriented straight out ends or at 90º to heater axis

Maximum Lead Wire Temperature: 842°F (450°C)

Voltage: 600V Optional styles of high temperature insulated lead wire and un-insulated ring or spade terminals are available to suit your application. Bare stranded heater leads up to 9″ long may be ordered with optional ceramic bead insulators. Longer lengths are available as lead wire options only. When ordering, specify lead orientation, style, length, and terminals.

Lead Wire

Insulated lead wire, 3/8″ stripped ends standard, oriented straight out ends or at 90º to heater axis

Maximum Lead Wire Temperature: 842°F (450°C)

Voltage: 600V Optional styles of high temperature insulated lead wire and un-insulated ring or spade terminals are available to suit your application. Bare stranded heater leads up to 9″ long may be ordered with optional ceramic bead insulators. Longer lengths are available as lead wire options only. When ordering, specify lead orientation, style, length, and terminals.

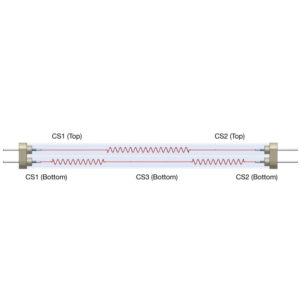

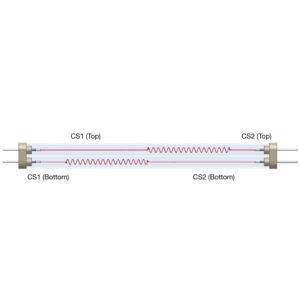

Winding Patterns

No options available for this section based on your selections

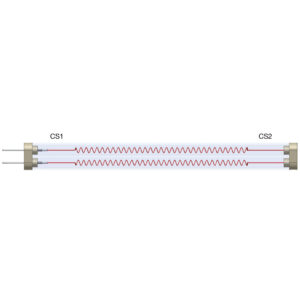

Winding Pattern A

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern A

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

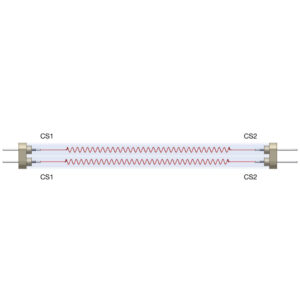

Winding Pattern B

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern B

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

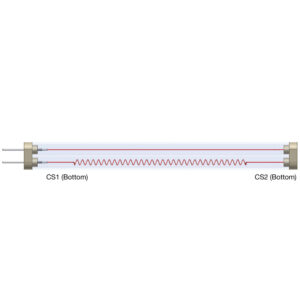

Winding Pattern C

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern C

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

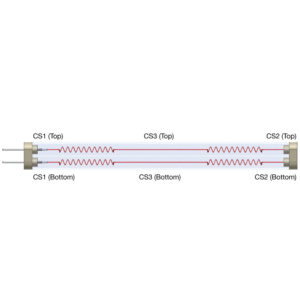

Winding Pattern D

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern D

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern E

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern E

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern F

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern F

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern G

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern G

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern H

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern H

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern J

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.

Winding Pattern J

Using alternate stretching configurations to achieve distributed wattage, Tempco can easily customize Gemini series heaters to fit your application.