Click or tap image to expand

Mightyband™ Coil Heaters

Refine Results

(6 filters)Cable Type

No options available for this section based on your selections

Round Cable

Heating element is embedded in MgO insulation inside a round tube.

Square Cable

Heating element is embedded in MgO insulation inside a square tube. Because of the flat surface, in some applications square cable allows better heat conduction and a faster start-up time.

Square Cable

Heating element is embedded in MgO insulation inside a square tube. Because of the flat surface, in some applications square cable allows better heat conduction and a faster start-up time.

Rectangular Cable

Heating element is embedded in MgO insulation inside a square tube. Because of the flat surface, in some applications rectangular cable allows better heat conduction and a faster start-up time.

Rectangular Cable

Heating element is embedded in MgO insulation inside a square tube. Because of the flat surface, in some applications rectangular cable allows better heat conduction and a faster start-up time.

Standard Configurations

No options available for this section based on your selections

Clamping Straps

Mightybands normally do not require clamping straps as the inside diameter of the coil is wound undersize for a screw fit. At times because of differences in the expansion and contraction in materials a clamping strap may be required to ensure circumferential clamping forces. Clamping straps also provide additional protection of the heater coils from accidental damage. If optional clamping strap is required, specify.

Clamping Straps

Mightybands normally do not require clamping straps as the inside diameter of the coil is wound undersize for a screw fit. At times because of differences in the expansion and contraction in materials a clamping strap may be required to ensure circumferential clamping forces. Clamping straps also provide additional protection of the heater coils from accidental damage. If optional clamping strap is required, specify.

Distributed Wattage

By specifically arranging a coiling pattern on the heater cable, heat distribution can be concentrated where it is needed. Useful to compensate for heat losses along the edges of the part being heated. Specify concentration.

Distributed Wattage

By specifically arranging a coiling pattern on the heater cable, heat distribution can be concentrated where it is needed. Useful to compensate for heat losses along the edges of the part being heated. Specify concentration.

Electrical Terminations

No options available for this section based on your selections

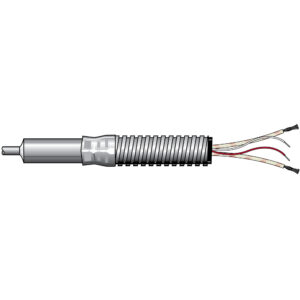

Type A: Stainless Steel Armor Cable

Type A1 – Rated to 482°F (250°C) – TGGT Fiberglass Wire

Type A2 – Rated to 450°F (232°C) – Teflon® Wire

Type A3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Flexible SS armor cable protects the leads against abrasion and contamination. Special plugs can be attached to heater leads and thermocouple leads.

Type A: Stainless Steel Armor Cable

Type A1 – Rated to 482°F (250°C) – TGGT Fiberglass Wire

Type A2 – Rated to 450°F (232°C) – Teflon® Wire

Type A3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Flexible SS armor cable protects the leads against abrasion and contamination. Special plugs can be attached to heater leads and thermocouple leads.

• The heating element wire to lead wire transition is done within the potting adapter. Potting adapter sizes are 5/16″ O.D. × 1-1/2″ long for heater cable diameters 0.188″ and smaller and 1/2″ × 1-1/2″ long for diameters above 0.188″. Other diameters and lengths are available, depending on design parameters.

• When the 1/2″ × 1-1/2″ long potting adapter is used for high temperature applications, a special heat sink collar is also used to help keep the transition from overheating.

• All transitions use 1150°F (621°C) braze joint between the heating element wire and the flexible lead wire.

• Normally the lead wire construction is a fiberglass braided insulation rated to 482°F (250°C). For high temperature applications an MGT (mica, fiberglass, Teflon® impregnation) insulation rated to 842°F (450°C) is used. All thermocouple leads use a fiberglass insulation rated to 900°F (482°C). Lead wires are selected to meet the amperage and temperature requirements of each specific heater.

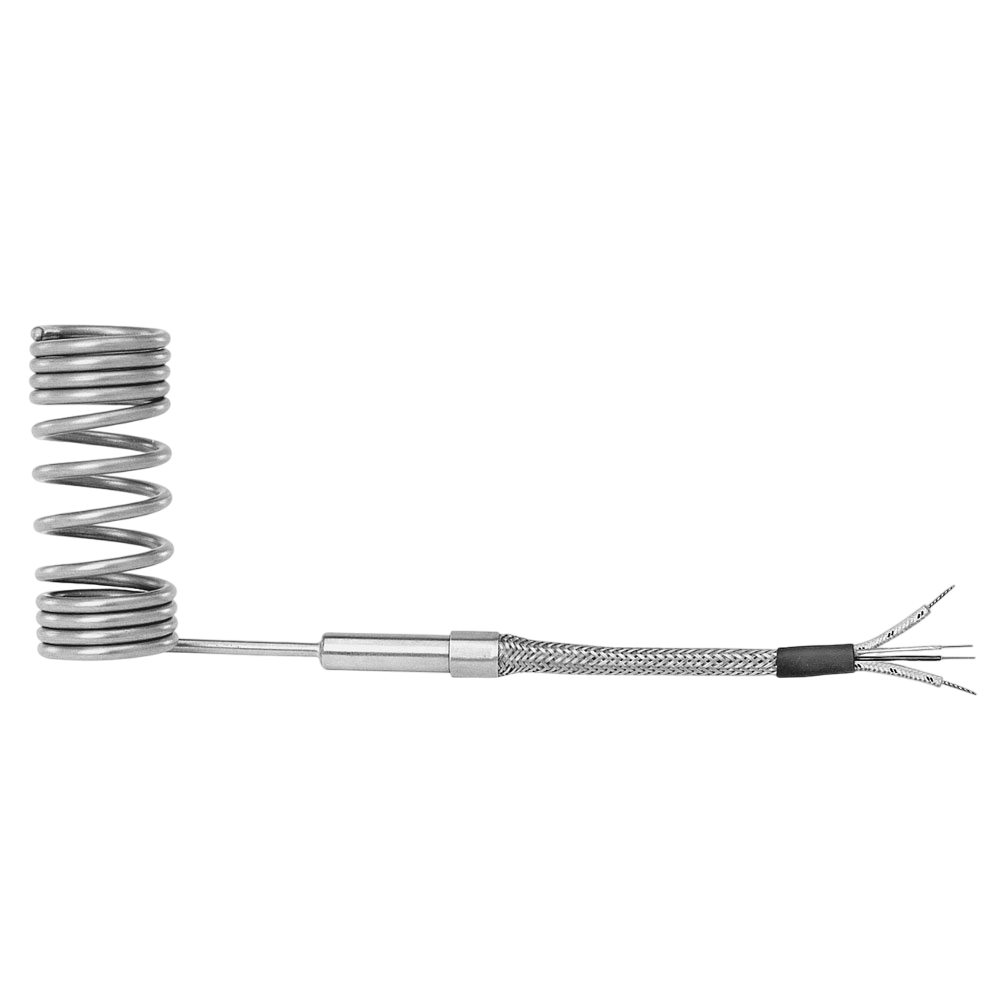

Type B: Stainless Steel Overbraid

Type B1 – Rated to 482°F (250°C) – TGGT Fiberlgass Wire

Type B2 – Rated to 450°F (232°C) – Teflon® Wire

Type B3 – Rated to 842°F (450°C) – MGT Fiberlgass Wire SS overbraid protects the leads against abrasion and allows more aggressive bending, which is not possible with armor cable. Special plugs can be attached to heater and thermocouple leads.

Type B: Stainless Steel Overbraid

Type B1 – Rated to 482°F (250°C) – TGGT Fiberlgass Wire

Type B2 – Rated to 450°F (232°C) – Teflon® Wire

Type B3 – Rated to 842°F (450°C) – MGT Fiberlgass Wire SS overbraid protects the leads against abrasion and allows more aggressive bending, which is not possible with armor cable. Special plugs can be attached to heater and thermocouple leads.

• The heating element wire to lead wire transition is done within the potting adapter. Potting adapter sizes are 5/16″ O.D. × 1-1/2″ long for heater cable diameters 0.188″ and smaller and 1/2″ × 1-1/2″ long for diameters above 0.188″. Other diameters and lengths are available, depending on design parameters.

• When the 1/2″ × 1-1/2″ long potting adapter is used for high temperature applications, a special heat sink collar is also used to help keep the transition from overheating.

• All transitions use 1150°F (621°C) braze joint between the heating element wire and the flexible lead wire.

• Normally the lead wire construction is a fiberglass braided insulation rated to 482°F (250°C). For high temperature applications an MGT (mica, fiberglass, Teflon® impregnation) insulation rated to 842°F (450°C) is used. All thermocouple leads use a fiberglass insulation rated to 900°F (482°C). Lead wires are selected to meet the amperage and temperature requirements of each specific heater.

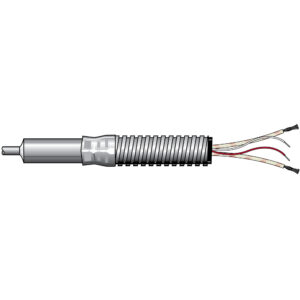

Type C: Galvanized Armor Cable

Type C1 – Rated to 482°F (250°C) – TGGT Fiberlgass Wire

Type C2 – Rated to 450°F (232°C) – Teflon® Wire

Type C3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Flexible galvanized armor cable protects the leads against abrasion and contamination. Special plugs can be attached to heater leads and thermocouple leads.

Type C: Galvanized Armor Cable

Type C1 – Rated to 482°F (250°C) – TGGT Fiberlgass Wire

Type C2 – Rated to 450°F (232°C) – Teflon® Wire

Type C3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Flexible galvanized armor cable protects the leads against abrasion and contamination. Special plugs can be attached to heater leads and thermocouple leads.

• The heating element wire to lead wire transition is done within the potting adapter. Potting adapter sizes are 5/16″ O.D. × 1-1/2″ long for heater cable diameters 0.188″ and smaller and 1/2″ × 1-1/2″ long for diameters above 0.188″. Other diameters and lengths are available, depending on design parameters.

• When the 1/2″ × 1-1/2″ long potting adapter is used for high temperature applications, a special heat sink collar is also used to help keep the transition from overheating.

• All transitions use 1150°F (621°C) braze joint between the heating element wire and the flexible lead wire.

• Normally the lead wire construction is a fiberglass braided insulation rated to 482°F (250°C). For high temperature applications an MGT (mica, fiberglass, Teflon® impregnation) insulation rated to 842°F (450°C) is used. All thermocouple leads use a fiberglass insulation rated to 900°F (482°C). Lead wires are selected to meet the amperage and temperature requirements of each specific heater.

Type M: Plain Leads

Standard

M1 – High temperature cement potting with TGGT (Teflon® tape, fiberglass, Teflon® treated fiberglass overbraid) insulated lead wire for 482°F (250°C) and silicone sealed is standard.

Optional

M2 – High temperature epoxy potting rated 450°F (232°C) with PTFE Teflon® lead wire for a better moisture seal.

M3 – High temperature cement potting with MGT (mica tape, Teflon® treated fiberglass overbraid) insulated lead wire for 842°F (450°C) and silicone sealed.

Type M: Plain Leads

Standard

M1 – High temperature cement potting with TGGT (Teflon® tape, fiberglass, Teflon® treated fiberglass overbraid) insulated lead wire for 482°F (250°C) and silicone sealed is standard.

Optional

M2 – High temperature epoxy potting rated 450°F (232°C) with PTFE Teflon® lead wire for a better moisture seal.

M3 – High temperature cement potting with MGT (mica tape, Teflon® treated fiberglass overbraid) insulated lead wire for 842°F (450°C) and silicone sealed.

- The heating element wire to lead wire transition is done within the potting adapter. Potting adapter sizes are 5/16″ O.D. × 1-1/2″ long for heater cable diameters 0.188″ and smaller and 1/2″ × 1-1/2″ long for diameters above 0.188″. Other diameters and lengths are available, depending on design parameters.

- When the 1/2″ × 1-1/2″ long potting adapter is used for high temperature applications, a special heat sink collar is also used to help keep the transition from overheating.

- All transitions use 1150°F (621°C) braze joint between the heating element wire and the flexible lead wire.

- Normally the lead wire construction is a fiberglass braided insulation rated to 482°F (250°C). For high temperature applications an MGT (mica, fiberglass, Teflon® impregnation) insulation rated to 842°F (450°C) is used. All thermocouple leads use a fiberglass insulation rated to 900°F (482°C). Lead wires are selected to meet the amperage and temperature requirements of each specific heater.

Type S: Fiberglass Sleeve

Type S1 – Rated to 482°F (250°C) – TGGT Fiberglass Wire

Type S2 – Rated to 450°F (232°C) – Teflon® Wire

Type S3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Fiberglass sleeve protects the leads against abrasion and allows more flexibility of lead wires. Special plugs can be attached to heater and thermocouple leads.

Type S: Fiberglass Sleeve

Type S1 – Rated to 482°F (250°C) – TGGT Fiberglass Wire

Type S2 – Rated to 450°F (232°C) – Teflon® Wire

Type S3 – Rated to 842°F (450°C) – MGT Fiberglass Wire Fiberglass sleeve protects the leads against abrasion and allows more flexibility of lead wires. Special plugs can be attached to heater and thermocouple leads.

• The heating element wire to lead wire transition is done within the potting adapter. Potting adapter sizes are 5/16″ O.D. × 1-1/2″ long for heater cable diameters 0.188″ and smaller and 1/2″ × 1-1/2″ long for diameters above 0.188″. Other diameters and lengths are available, depending on design parameters.

• When the 1/2″ × 1-1/2″ long potting adapter is used for high temperature applications, a special heat sink collar is also used to help keep the transition from overheating.

• All transitions use 1150°F (621°C) braze joint between the heating element wire and the flexible lead wire.

• Normally the lead wire construction is a fiberglass braided insulation rated to 482°F (250°C). For high temperature applications an MGT (mica, fiberglass, Teflon® impregnation) insulation rated to 842°F (450°C) is used. All thermocouple leads use a fiberglass insulation rated to 900°F (482°C). Lead wires are selected to meet the amperage and temperature requirements of each specific heater.

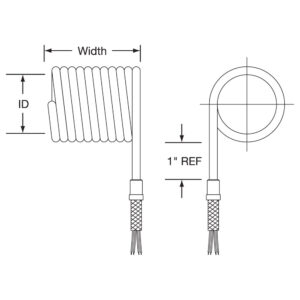

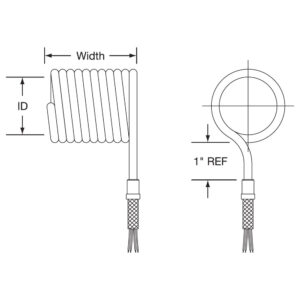

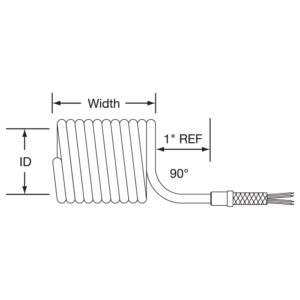

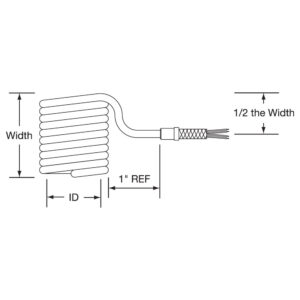

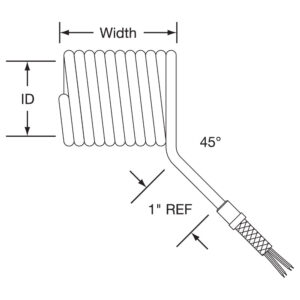

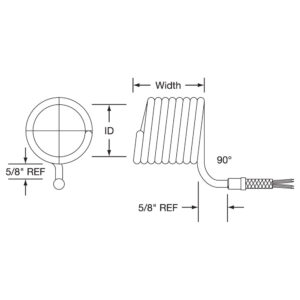

Lead Orientations

No options available for this section based on your selections

Thermocouple Calibration

No options available for this section based on your selections

Additional Options

No options available for this section based on your selections

Explosion or Moisture Resistant Box

Mightyband coil heaters can be used for immersion heating and/or in-line heating of liquids, gases or air. The built-in thermocouple provides a self-contained heating unit, eliminating the need for separate thermowells, and is available with standard NPT or special fittings. The outside diameter (O.D.) of the coil must be smaller than the fitting being used for proper fit to the mating part. The wiring can be protected from hazardous environments by attaching explosion or moisture-proof boxes. Consult Tempco with your requirements.

Explosion or Moisture Resistant Box

Mightyband coil heaters can be used for immersion heating and/or in-line heating of liquids, gases or air. The built-in thermocouple provides a self-contained heating unit, eliminating the need for separate thermowells, and is available with standard NPT or special fittings. The outside diameter (O.D.) of the coil must be smaller than the fitting being used for proper fit to the mating part. The wiring can be protected from hazardous environments by attaching explosion or moisture-proof boxes. Consult Tempco with your requirements.

NPT Pipe Fittings

Mightyband coil heaters can be used for immersion heating and/or in-line heating of liquids, gases or air. The built-in thermocouple provides a self-contained heating unit, eliminating the need for separate thermowells. Available with standard NPT fittings or special fittings. The outside diameter (O.D.) of the coil must be smaller than the fitting being used for proper fit to the mating part. Consult Tempco with your requirements.

NPT Pipe Fittings

Mightyband coil heaters can be used for immersion heating and/or in-line heating of liquids, gases or air. The built-in thermocouple provides a self-contained heating unit, eliminating the need for separate thermowells. Available with standard NPT fittings or special fittings. The outside diameter (O.D.) of the coil must be smaller than the fitting being used for proper fit to the mating part. Consult Tempco with your requirements.

Star Wound Coil

Star wound formations are usually inserted into pipes or ducts and are used to heat moving air or liquids. The offset coils create a turbulent flow. This allows the flowing material to have better contact with the heater surface, resulting in more efficient heat transfer.

Star Wound Coil

Star wound formations are usually inserted into pipes or ducts and are used to heat moving air or liquids. The offset coils create a turbulent flow. This allows the flowing material to have better contact with the heater surface, resulting in more efficient heat transfer.

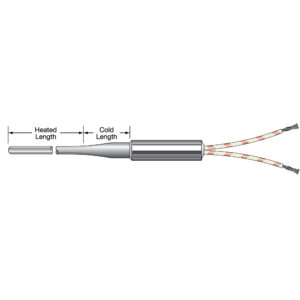

Type ND – Neck Down

The availability of heaters with optional cold heater cable end depends on the electrical ratings and materials used for each heater design. Consult Tempco for the availability of these options.

Type ND – Neck Down

The availability of heaters with optional cold heater cable end depends on the electrical ratings and materials used for each heater design. Consult Tempco for the availability of these options.

Type NW – Built-In Cold Wire

The availability of heaters with optional cold heater cable end depends on the electrical ratings and materials used for each heater design. Consult Tempco for the availability of these options.

Type NW – Built-In Cold Wire

The availability of heaters with optional cold heater cable end depends on the electrical ratings and materials used for each heater design. Consult Tempco for the availability of these options.