Click or tap image to expand

Hi-Density Miniature Cartridge Heaters

- 1/8″ diameter

- 5/32″ diameter

- 3/16″ diameter

Refine Results

(8 filters)Termination Location

No options available for this section based on your selections

Single-Ended Straight Termination

The Electrical Termination is located at one end of the heater and exits straight out from the heater.

Single-Ended Straight Termination

The Electrical Termination is located at one end of the heater and exits straight out from the heater.

Electrical Terminations

No options available for this section based on your selections

Type M3: Teflon® End Plug Seal with Teflon® Leads

Standard Termination for Hi-Density Miniature Cartridge Heaters. A moisture resistant Teflon® seal that is swaged in during the manufacturing process with Teflon® insulated lead wire.

Type M3: Teflon® End Plug Seal with Teflon® Leads

Standard Termination for Hi-Density Miniature Cartridge Heaters. A moisture resistant Teflon® seal that is swaged in during the manufacturing process with Teflon® insulated lead wire.

Minimum 1/2″ unheated section at lead end is required.

24 ga Teflon® insulated leads temperature rating: 392°F (200°C)

Moisture resistant swaged Teflon® seal.

Standard 10″ (254 mm) leads. Specify longer leads.

Type N: External Pins with Leads

Flexible stranded lead wires have fiberglass insulation and are connected to 1-1/4″ (32 mm) long solid conductors. Silicone rubber coated fiberglass sleeving insulates the pin/lead wire connection.

Type N: External Pins with Leads

Flexible stranded lead wires have fiberglass insulation and are connected to 1-1/4″ (32 mm) long solid conductors. Silicone rubber coated fiberglass sleeving insulates the pin/lead wire connection.

Minimum 1/4″ unheated section at lead end is required.

24 ga ultralead leads temperature rating: 482°F (250°C)

Silicone rubber coated fiberglass sleeving temperature rating: 392°F (200°C)

Leads externally crimped to nickel pins

Standard 10″ (254 mm) leads. Specify longer leads.

Type F: Internally Connected Flexible Leads

The fiberglass lead wires are internally connected to the terminal pins. This lead termination provides flexibility, permitting the lead wires to be sharply bent as they exit the heater.

Type F: Internally Connected Flexible Leads

The fiberglass lead wires are internally connected to the terminal pins. This lead termination provides flexibility, permitting the lead wires to be sharply bent as they exit the heater.

Minimum 1/2″ unheated section at lead end is required.

High temperature fiberglass leads temperature rating: 842°F (450°C)

Standard 10″ (254 mm) leads. Specify longer leads.

Type W: Wire Braided Leads

Stainless steel braid over fiberglass leads offers sharp bending not possible with armor cable, as well as abrasion protection.

Type W: Wire Braided Leads

Stainless steel braid over fiberglass leads offers sharp bending not possible with armor cable, as well as abrasion protection.

Minimum 1/4″ unheated section is required.

Standard lead wire temperature rating: 842°F (450°C)

Standard 10″ (254 mm) cable over 12″ (305 mm) leads. Specify longer leads or cable.

Type C1B: Stainless Steel Armor Cable, Mechanically Fastened

Armor cable provides the maximum in protection for abrasive, jagged environments. The coupling between the cartridge and the armor cable is mechanically fastened.

Type C1B: Stainless Steel Armor Cable, Mechanically Fastened

Armor cable provides the maximum in protection for abrasive, jagged environments. The coupling between the cartridge and the armor cable is mechanically fastened.

Minimum 1/4″ unheated section is required.

Standard fiberglass lead wire temperature rating: 482°F (250°C)

Standard 10″ (254 mm) cable over 12″ (305 mm) leads. Specify longer leads or cable.

Request Other Electrical Termination

If your filter selections do not return your desired results from our standard configurations, please continue to Refine Results for your specifications. When you are finished, save your selections with the Save Results for Quote button (at the right of this page) and choose Request for Quote for further assistance.

Request Other Electrical Termination

If your filter selections do not return your desired results from our standard configurations, please continue to Refine Results for your specifications. When you are finished, save your selections with the Save Results for Quote button (at the right of this page) and choose Request for Quote for further assistance.

Sheath Options

No options available for this section based on your selections

Type R4: Bent Cartridge

The heater sheath is bent up to 90°. The bend is through a required unheated section. The standard sheath extension past the bend is 1″. Specify when ordering if a longer sheath is required. Contact Tempco for bend radius details.

Type R4: Bent Cartridge

The heater sheath is bent up to 90°. The bend is through a required unheated section. The standard sheath extension past the bend is 1″. Specify when ordering if a longer sheath is required. Contact Tempco for bend radius details.

Type LR: Locating Ring

A locating ring can be attached to the heater to aid in positioning the heater for the application. The default position of the ring is 1/4″ from the lead end. Specify the position of the ring when ordering.

Type LR: Locating Ring

A locating ring can be attached to the heater to aid in positioning the heater for the application. The default position of the ring is 1/4″ from the lead end. Specify the position of the ring when ordering.

Sensor Options

No options available for this section based on your selections

Type TJ1 and TK1: Grounded at Disc End

The thermocouple junction is grounded to the sheath at the disc end and packed with MgO. The concave end disc is filled with silver solder and ground flat. When inserted into a flat end blind hole, it will provide fast responsive temperature readings. Widely used in Hot Runner mold probes.

Type TJ1 and TK1: Grounded at Disc End

The thermocouple junction is grounded to the sheath at the disc end and packed with MgO. The concave end disc is filled with silver solder and ground flat. When inserted into a flat end blind hole, it will provide fast responsive temperature readings. Widely used in Hot Runner mold probes.

TJ1 Type J thermocouple

TK1 Type K thermocouple

Minimum sheath length: 3″ for 1/4″, 3/8″ and 1/2″ diameter. 4″ for 5/8″ and 3/4″ diameter.

10″ leads are standard for both heater and

thermocouple. Leads are internally connected. Specify longer leads.

| ANSI Code | Conductor Characteristics | Temperature Ranged | ||

|---|---|---|---|---|

| Postivie | Negative | °F | °C | |

| J | Iron (Magnetic) | Constantan (Non-Magnetic) | 0 to 1400 | -17 to 760 |

| K | Chrome (Non-Magnetic)_ | Alumel (Magnetic) | 0 to 2300 | -17 to 1260 |

| For other thermocouple types, constult Tempco. | ||||

Scroll for more

Type TJ2 and TK2: Ungrounded at Disc End

The thermocouple junction is ungrounded, located at the end of the heater section, 1/8″ behind the end disc and packed with MgO. Only provides reference temperature reading of the part being heated – slower response.

Type TJ2 and TK2: Ungrounded at Disc End

The thermocouple junction is ungrounded, located at the end of the heater section, 1/8″ behind the end disc and packed with MgO. Only provides reference temperature reading of the part being heated – slower response.

TJ2 Type J thermocouple

TK2 Type K thermocouple

Minimum sheath length: 3″ for 1/4″, 3/8″ and 1/2″ diameter. 4″ for 5/8″ and 3/4″ diameter.

10″ leads are standard for both heater and

thermocouple. Leads are internally connected. Specify longer leads.

| ANSI Code | Conductor Characteristics | Temperature Ranged | ||

|---|---|---|---|---|

| Postivie | Negative | °F | °C | |

| J | Iron (Magnetic) | Constantan (Non-Magnetic) | 0 to 1400 | -17 to 760 |

| K | Chrome (Non-Magnetic)_ | Alumel (Magnetic) | 0 to 2300 | -17 to 1260 |

| For other thermocouple types, constult Tempco. | ||||

Scroll for more

Type TJ3 and TK3: Ungrounded at Center

The thermocouple junction is ungrounded and is located in the center of the length and diameter of the cartridge heater. It provides internal temperature readings of the heater core. Generally used for research applications and is not recommended for controlling process temperatures.

Type TJ3 and TK3: Ungrounded at Center

The thermocouple junction is ungrounded and is located in the center of the length and diameter of the cartridge heater. It provides internal temperature readings of the heater core. Generally used for research applications and is not recommended for controlling process temperatures.

TJ3 Type J thermocouple

TK3 Type K thermocouple

Minimum sheath length: 3″ for 1/4″, 3/8″ and 1/2″ diameter. 4″ for 5/8″ and 3/4″ diameter.

10″ leads are standard for both heater and

thermocouple. Leads are internally connected. Specify longer leads.

| ANSI Code | Conductor Characteristics | Temperature Ranged | ||

|---|---|---|---|---|

| Postivie | Negative | °F | °C | |

| J | Iron (Magnetic) | Constantan (Non-Magnetic) | 0 to 1400 | -17 to 760 |

| K | Chrome (Non-Magnetic)_ | Alumel (Magnetic) | 0 to 2300 | -17 to 1260 |

| For other thermocouple types, constult Tempco. | ||||

Scroll for more

Type TJ4 and TK4: Grounded at Center

The thermocouple junction is grounded to the sheath in a 1/2″ unheated section located in the center of the cartridge length unless otherwise specified. It provides good temperature readings with quick response.

Type TJ4 and TK4: Grounded at Center

The thermocouple junction is grounded to the sheath in a 1/2″ unheated section located in the center of the cartridge length unless otherwise specified. It provides good temperature readings with quick response.

TJ4 Type J thermocouple

TK4 Type K thermocouple

Minimum sheath length: 3″ for 1/4″, 3/8″ and 1/2″ diameter. 4″ for 5/8″ and 3/4″ diameter.

10″ leads are standard for both heater and

thermocouple. Leads are internally connected. Specify longer leads.

| ANSI Code | Conductor Characteristics | Temperature Ranged | ||

|---|---|---|---|---|

| Postivie | Negative | °F | °C | |

| J | Iron (Magnetic) | Constantan (Non-Magnetic) | 0 to 1400 | -17 to 760 |

| K | Chrome (Non-Magnetic)_ | Alumel (Magnetic) | 0 to 2300 | -17 to 1260 |

| For other thermocouple types, constult Tempco. | ||||

Scroll for more

Type TJ5 and TK5: Grounded at Lead End

The thermocouple junction is grounded to the sheath at the lead end. A minimum of 3/8″ of cold section is required. It provides good temperature readings with quick response.

Type TJ5 and TK5: Grounded at Lead End

The thermocouple junction is grounded to the sheath at the lead end. A minimum of 3/8″ of cold section is required. It provides good temperature readings with quick response.

TJ5 Type J thermocouple

TK5 Type K thermocouple

Minimum sheath length: 3″ for 1/4″, 3/8″ and 1/2″ diameter. 4″ for 5/8″ and 3/4″ diameter.

10″ leads are standard for both heater and

thermocouple. Leads are internally connected. Specify longer leads.

Note: For a complete selection of standard heaters with built-in Type J thermocouple for Hot Runner, please see the Pennybottom Cartridge Heater Section

| ANSI Code | Conductor Characteristics | Temperature Ranged | ||

|---|---|---|---|---|

| Postivie | Negative | °F | °C | |

| J | Iron (Magnetic) | Constantan (Non-Magnetic) | 0 to 1400 | -17 to 760 |

| K | Chrome (Non-Magnetic)_ | Alumel (Magnetic) | 0 to 2300 | -17 to 1260 |

| For other thermocouple types, constult Tempco. | ||||

Scroll for more

Power Variations

No options available for this section based on your selections

Type DW: Distributed Wattage

Cartridge heaters can be designed to vary the wattage along the length of the heater. Specify number of zones and the required watts and length per zone starting from the disk end. Leads can be connected externally or internally. Picture shows a heater with Type N externally connected leads. Heaters with other terminations may require a longer cold section at the lead end.

Type DW: Distributed Wattage

Cartridge heaters can be designed to vary the wattage along the length of the heater. Specify number of zones and the required watts and length per zone starting from the disk end. Leads can be connected externally or internally. Picture shows a heater with Type N externally connected leads. Heaters with other terminations may require a longer cold section at the lead end.

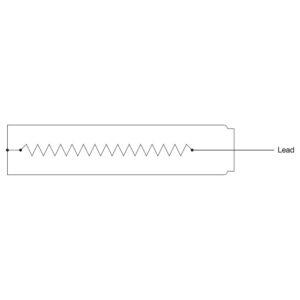

Type GJ: Grounded Element Winding

For DC applications where the electrical circuit is negative grounded, the cartridge heater can be designed with one side of the element winding grounded to the sheath and a single lead wire exiting the cartridge heater.

Type GJ: Grounded Element Winding

For DC applications where the electrical circuit is negative grounded, the cartridge heater can be designed with one side of the element winding grounded to the sheath and a single lead wire exiting the cartridge heater.

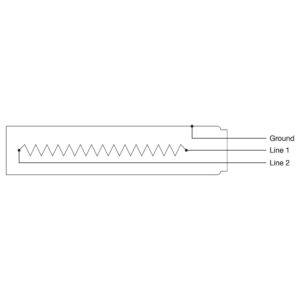

Type GL: Ground Lead/Sheath

For those applications requiring a separate ground lead attached to the cartridge heater sheath. Standard ground lead wire is a 10″ long insulated stranded conductor. Optional insulated and color coded leads are available.

Type GL: Ground Lead/Sheath

For those applications requiring a separate ground lead attached to the cartridge heater sheath. Standard ground lead wire is a 10″ long insulated stranded conductor. Optional insulated and color coded leads are available.

Available through the Hi-Density Cartridge Heater Terminator Program for 2nd Day Delivery

Additional Options

No options available for this section based on your selections

Type TM: Thermistor

Tempco has the ability to custom design cartridge heaters with built-in temperature sensors such as thermistors and RTDs. For specific applications that have a limited or single set point range, thermistors or RTDs in conjunction with simple electronic controllers can be an economical choice. NOTE: For thermocouples see page 2-58.

Type TM: Thermistor

Tempco has the ability to custom design cartridge heaters with built-in temperature sensors such as thermistors and RTDs. For specific applications that have a limited or single set point range, thermistors or RTDs in conjunction with simple electronic controllers can be an economical choice. NOTE: For thermocouples see page 2-58.

Type RD: RTD Temperature Sensor

Tempco has the ability to custom design cartridge heaters with built-in temperature sensors such as thermistors and RTDs. For specific applications that have a limited or single set point range, thermistors or RTDs in conjunction with simple electronic controllers can be an economical choice. NOTE: For thermocouples see page 2-58.

Type RD: RTD Temperature Sensor

Tempco has the ability to custom design cartridge heaters with built-in temperature sensors such as thermistors and RTDs. For specific applications that have a limited or single set point range, thermistors or RTDs in conjunction with simple electronic controllers can be an economical choice. NOTE: For thermocouples see page 2-58.

Standard Electrical Tests & Optional Test Reports

Standard Electrical Tests and Optional Test Reports 1. Resistance test — measures ohms at room temperature. 2. IR (insulation resistance) test — measures the insulation resistance to the flow of current. Standard test is done at 500VDC. 3. Hipot (high potential) test — a high voltage is applied between a product’s current carrying conductors and its metallic enclosure to verify that the insulation is sufficient to protect the operator from electrical shock. 4. Leakage current test — measures the current that flows from any conductive part to ground. 5. Heaters can be serialized and test reports can be sent with each shipment if required. Contact Tempco with your requirements.

Standard Electrical Tests & Optional Test Reports

Standard Electrical Tests and Optional Test Reports 1. Resistance test — measures ohms at room temperature. 2. IR (insulation resistance) test — measures the insulation resistance to the flow of current. Standard test is done at 500VDC. 3. Hipot (high potential) test — a high voltage is applied between a product’s current carrying conductors and its metallic enclosure to verify that the insulation is sufficient to protect the operator from electrical shock. 4. Leakage current test — measures the current that flows from any conductive part to ground. 5. Heaters can be serialized and test reports can be sent with each shipment if required. Contact Tempco with your requirements.

Die Penetrant Test

This non-destructive testing can detect imperfections in weld joints. For critical applications, each individual heater’s weld joints by end cap and fittings can be tested. Certified test reports will be sent with each shipment. Consult Tempco for details.

Die Penetrant Test

This non-destructive testing can detect imperfections in weld joints. For critical applications, each individual heater’s weld joints by end cap and fittings can be tested. Certified test reports will be sent with each shipment. Consult Tempco for details.

Hydrostatic Pressure Test

Cartridge heaters with attached pipe fittings can be pressure tested to your specifications at Tempco. Our in-house testing capabilities can ensure that your products meet your exact specifications. Contact Tempco with your requirements.

Hydrostatic Pressure Test

Cartridge heaters with attached pipe fittings can be pressure tested to your specifications at Tempco. Our in-house testing capabilities can ensure that your products meet your exact specifications. Contact Tempco with your requirements.