Click or tap image to expand

Cast-In Semiconductor Manufacturing Heaters

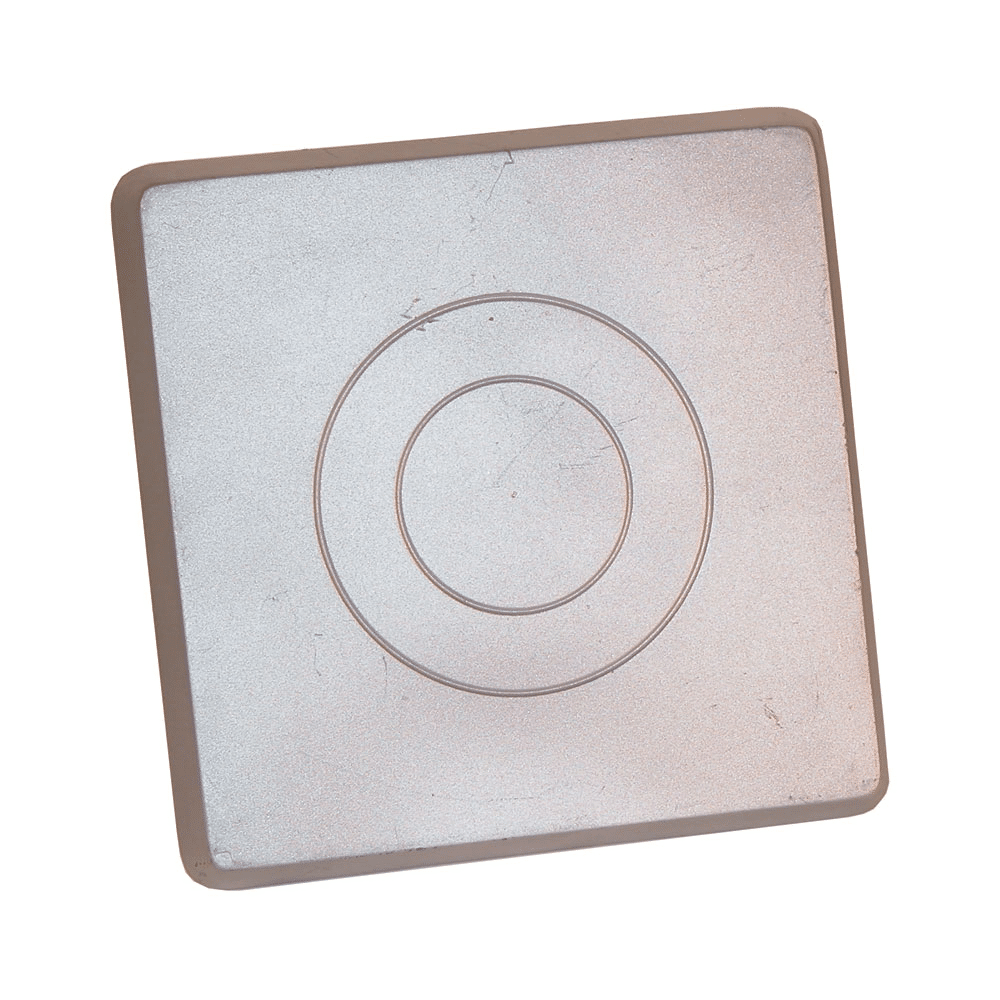

Cast-In Thermal Platens for Wave Solder & Reflow Surface Mount Equipment

Tempco’s highly engineered platens are capable of maintaining a temperature gradient of 5°F (2.77°C) across the entire working surface of the heater platen at the process operating temperature. The innovative design of this cast-in thermal platen incorporates the dual functions of being both a radiant and a convection heat source.

Cast-In Heaters for Wafer Processing

Tempo offers a complete selection of highly customized semi-conductor process heaters which include:

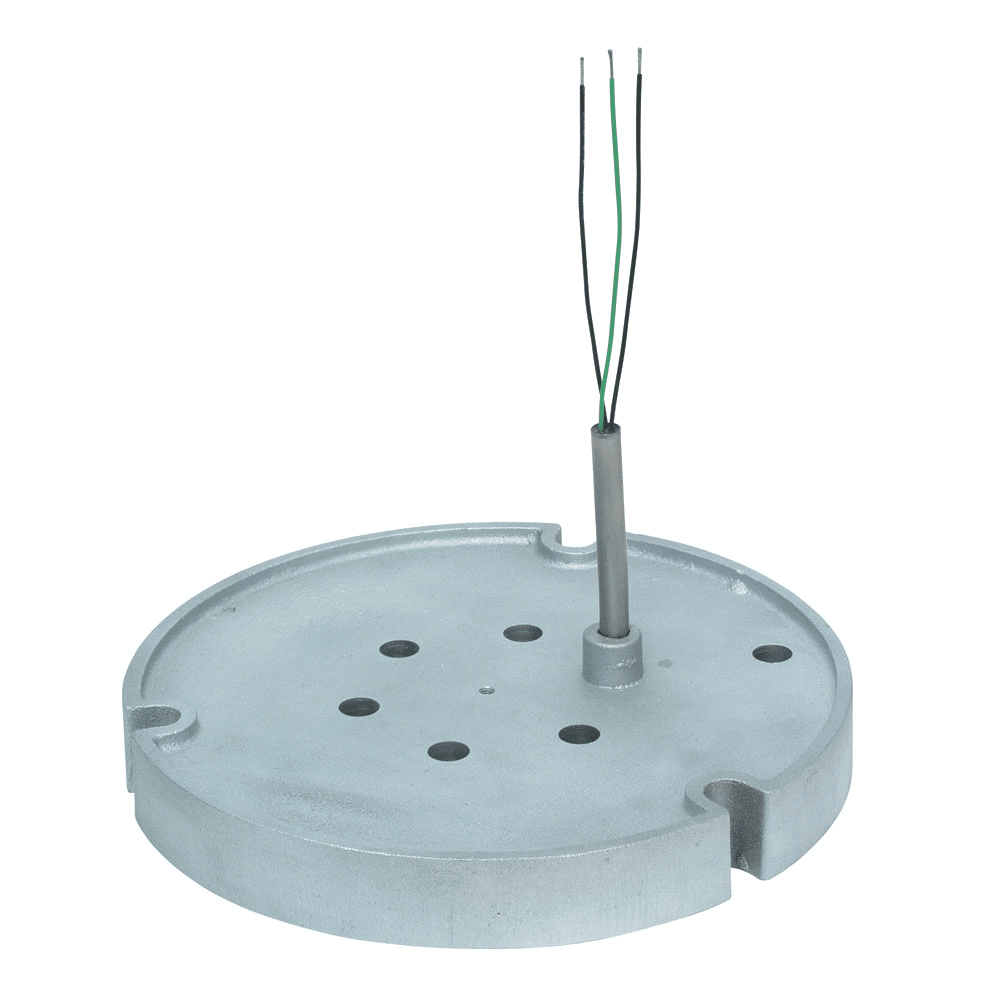

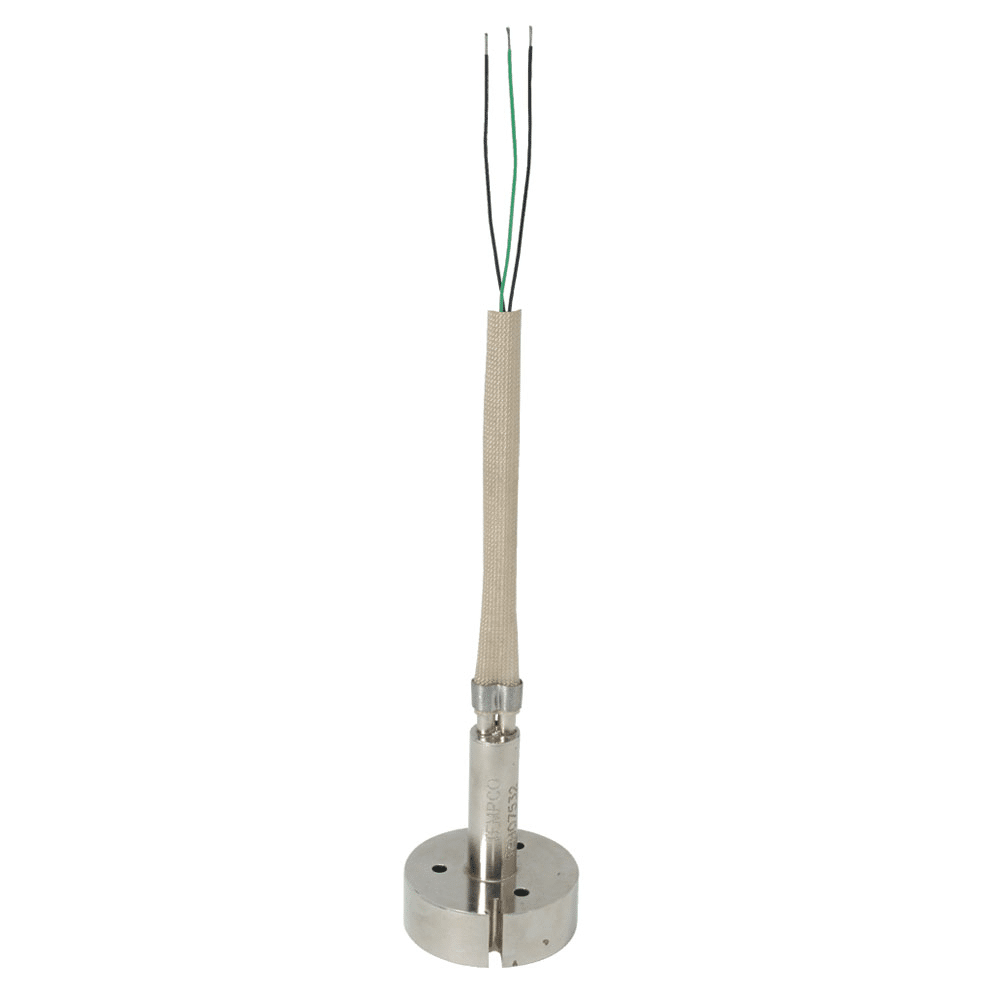

- Pedestal Heaters

- Pedestal Heaters with Integrated Cooling Capabilities

- Bake Platen Heaters

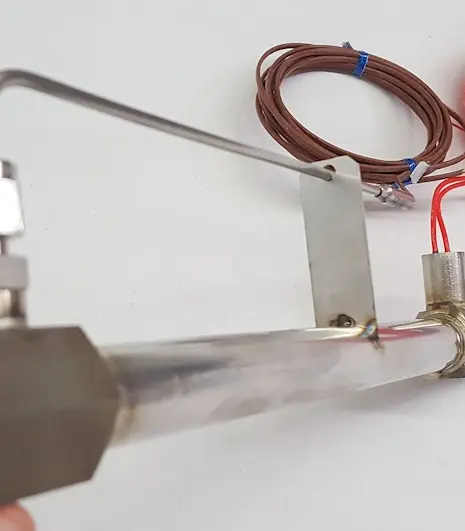

- High-Temperature Platen Heaters with Interference Press Fit Tubular or Cable Heating Elements.

For this type of platen heater construction, the available base alloys are:

- Aluminum

- Brass

- Bronze

Design Features:

- Casting Maximum Surface Temperatures

- Aluminum Alloy 319: 700°F (371°C)

- Aluminum Alloy 356: 750°F (399°C)

- Interference Press Fit Construction – maximum surface temperature depends on base alloy used

- Surface Finish – Hard-Coat Anodized

- Built-in Temperature Sensors ✴ Selection of heating element and cooling tube terminations

In order to satisfy the stringent requirements of the industry, these products are manufactured under rigid quality control standards. Specific attention is directed to the heating element design and the casting processes. Our metallurgical knowledge and foundry expertise are the catalyst for producing cast-in heaters with the precise heat profiles and temperature gradient required for the process.

Tempco’s state-of-the-art CNC machining capabilities will ensure that the working surface requirements of the part are precisely machined to customer requirements, including extremely flat surfaces, to within 0.0005 in (0.0127 mm) for optimizing the performance of the application.

Made-To-Spec Cast-In Heaters for Semiconductor Processing

Start with Tempco’s Cast-in Heater Specs & Tolerances guide for technical assistance, engineering data, and available options. Then, provide your design drawings with dimensions, critical tolerances, watts, volts and any other features or special specifications and we’ll create it.